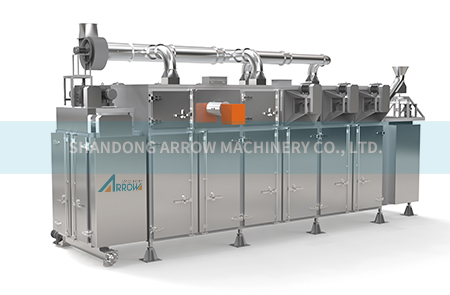

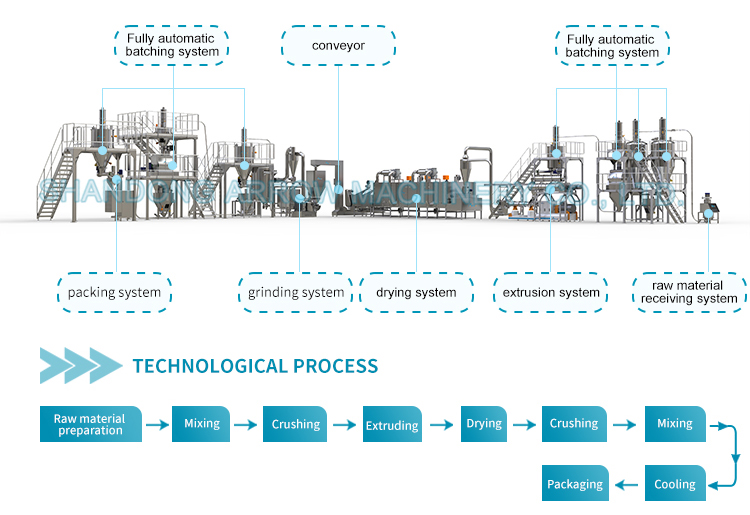

This process line uses rice,corn,beans and kinds of grains as raw materials.Through extruding ,inflating,drying,crushing and mixing ,it could produce many kinds of nutrition powder,such as baby rice powder,sesame paste,beans powder and so on.This line could finish all the process automatically from the feeding to the end.It has features of easy operation,without leak of powder dust,sanitation,saving energy and easy to add all kinds of raw materials and nutriment.Pre-galatinized strach is widely used in texitle,food process,oil drilling,paper,contruction industries etc.

With the improvement of people’s living standards, health care products and nutritional powders have gradually entered thousands of households in the form of gifts. People who have come out of the traditional diet structure start to look for functional foods that are good for health and longevity after they have enough food and clothing. The knowledge of nutrition is also widely used. The Nutrition Powder /Baby Rice Powder process Line improved by Shandong Arrow Company is a set of automatic nutritional powder production line developed by itself on the basis of absorbing foreign technology. The starch in the raw grain changes its properties, which is conducive to the absorption of the human body, and its nutritional value is higher than that of traditional processing techniques. Output:250-450kg/h, 300-600kg/h, 1-1.7t/h, 1.5-3.5t/h, 3-4.5t/h.

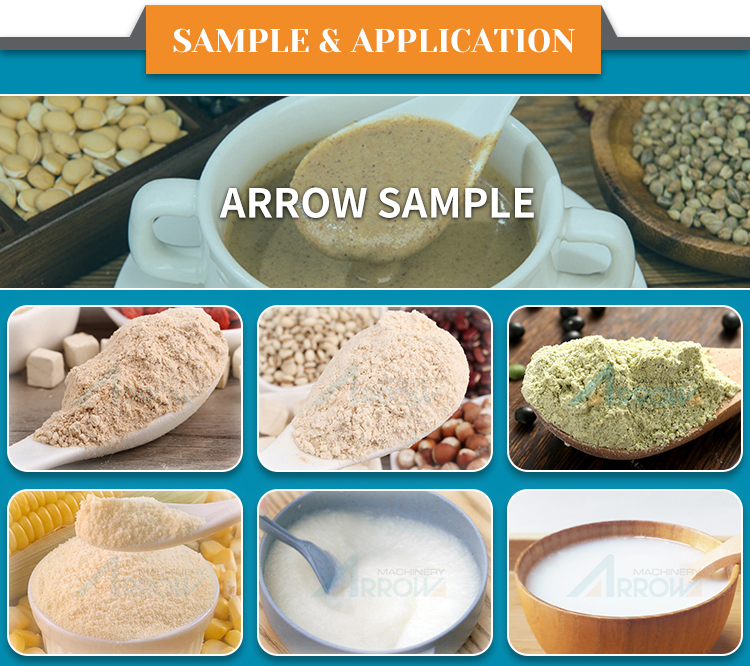

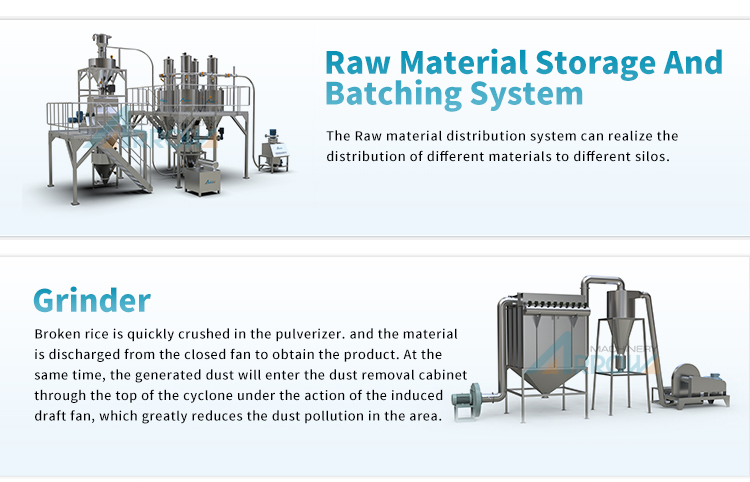

The production line uses corn flour, rice flour, millet flour, brown rice flour, flour, rice, corn, beans and other grain flour as the main raw materials, with vegetables, fruits, eggs, meat and other optional ingredients, adding calcium and phosphorus, iron and other minerals and vitamins are mixed, extruded, dried, crushed and other processes to gelatinize the grain starch and ripen the protein, and process it into five grain nutrition powder, infant nutrition rice flour, baby rice flour, sesame paste and soybean powder and other products.

Nutrient powder refers to grains as the main raw material (corn, rice, millet, wheat, oats, yam, konjac), etc., plus various beans such as black beans, red beans, barley, black sesame, etc.), accompanied by vegetables, fruits, Eggs, meat and other selective ingredients, adding calcium, phosphorus, iron and other minerals and vitamins, etc., through the extrusion process to gelatinize the grain starch and mature the protein, process it into a new era of convenience, strong taste and nutrition. Nutritional supplement food. They are collectively referred to as nutrition powder. According to different product formulas, nutrition powder includes red bean barley powder, yam powder, whole grain powder, and five grain meal replacement powder.

Five-grain powder is a powder product that is refined after grinding various grains, miscellaneous grains, beans and dual-purpose raw materials for medicine and food. It is a general term for five-grain flour products. Rather than “rice, millet, millet, wheat, and bean” in the narrow sense. In a broad sense, whole grains include: rice, millet, brown rice, corn, polished rice, glutinous rice, barley, black rice, red rice, soybeans, red beans, mung beans, black beans, buckwheat, oats, wheat, sorghum, sweet potatoes, etc. The puffed powder made of similar raw materials is collectively referred to as whole grain powder.

Nutrition Powder /Baby Rice Powder process LineNutrition Powder /Baby Rice Powder process Line

Nutrition Powder /Baby Rice Powder process Line

Production line advantage

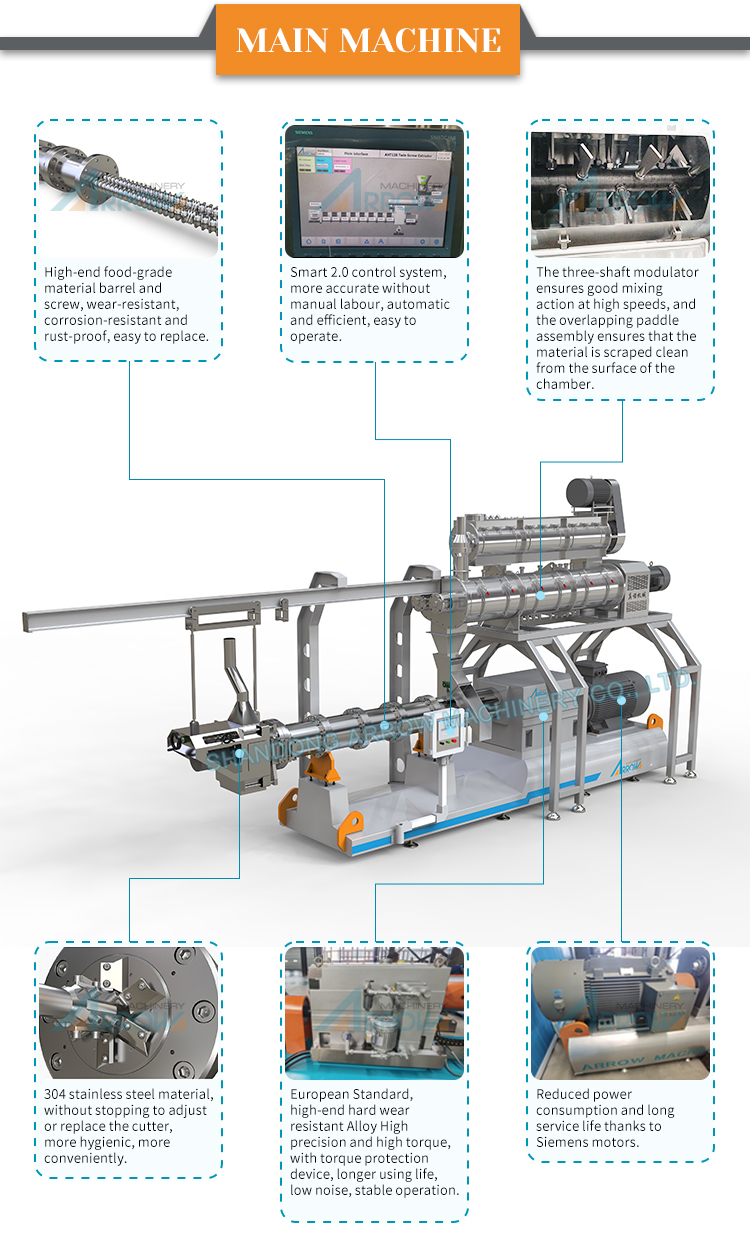

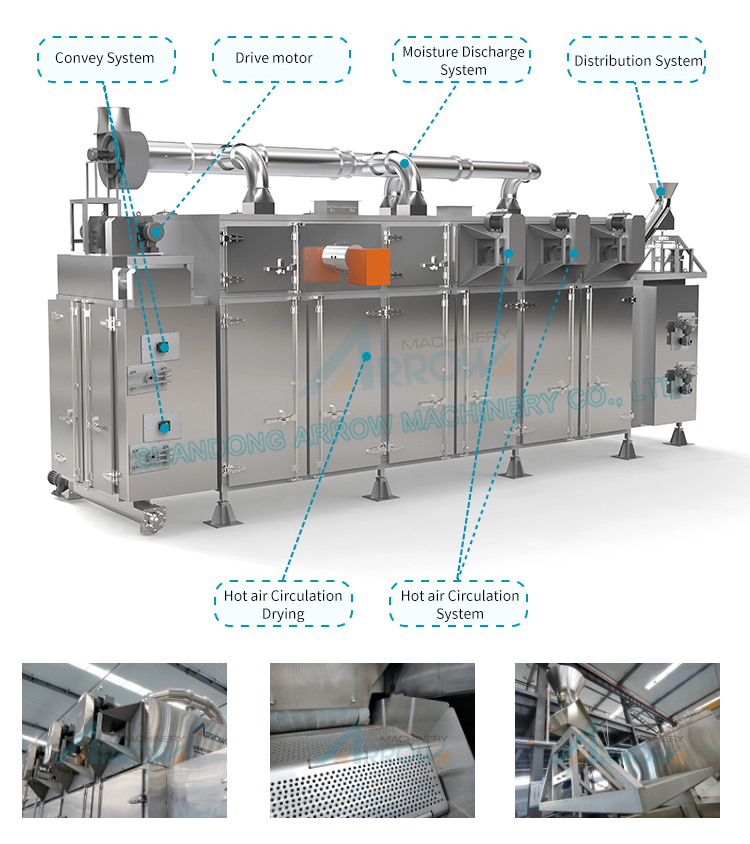

Technical aspect: Shandong Arrow nutritional rice noodle production line adopts twin-screw extrusion technology to replace the new technology of traditional cooking rice noodle production. The nutritional powder food production line has obtained the twin-screw extrusion technology developed by our company. Traditional nutritional powder processing methods have many disadvantages such as low efficiency, problems, and small-scale production. In the nutritional powder food production line, the twin-screw extrusion technology makes up for all these deficiencies, which means that it can not only process grain raw materials, such as buckwheat, oats, etc. It can also produce more nutritious and healthy food that is beneficial to the body. All parts of our nutrition powder machine are made of food-grade stainless steel, which is very advanced and of high quality. Our principle is to ensure that all products on the nutritional powder food production line meet food and hygiene standards, especially the baby food produced by our nutritional powder machinery and equipment is healthy. Operational aspects: Shandong Arrow nutritional rice noodle production line integrates mixing, cooking, ripening, puffing, sterilization and packaging, and does not require a boiler. The production process is simplified, efficient and environmentally friendly. This nutritional powder production line can automatically complete all processes from feeding to finishing, and can process and produce a large amount of nutritional powder in a short time. The nutrition powder machine always saves you a lot of working time and manpower, and improves work efficiency.

It has the characteristics of easy operation, no dust leakage, sanitation, energy saving, easy to add various raw materials and nutrition, during the mechanical processing of baby food powder, it can add probiotics and vitamins needed by children.