Soybean protein: Soy protein that has been organized and has a stable network structure.

Tissue protein has different shapes such as granular, lump, flake, and filament, with different shades of yellow-brown, and its network structure is oriented to form elastic and tough fiber bundles or layers, which makes it similar when eaten. The bite of carnivorous muscle tissue. Typical tissue protein contains about 60% protein.

Industrial production methods

(1)Extrusion method

(1) Take the defatted soybean meal as raw material, and organize it with the shear force formed by the extruder. The protein produced by this method, also known as extruded protein, can be used as a base for artificial meat or as an increment for meat products

(2)Textile Law

Using soybean protein isolate as a raw material and using a manufacturing process similar to rayon, the soy protein filamentary fiber is called spinning protein. It can be used as muscle fiber material for high-quality meat-like products. This method has not yet been industrialized on a large scale.

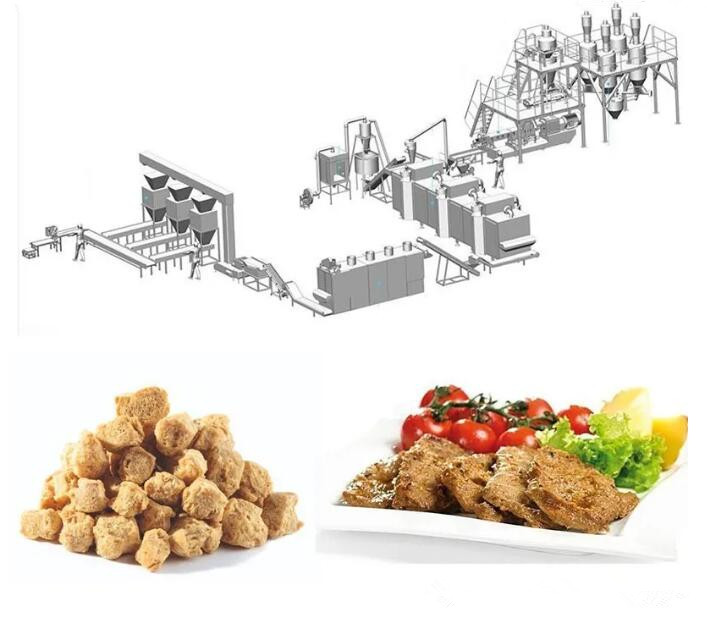

Soybean tissue protein production line

Soybean tissue protein is mainly passed through a twin screw extruder to defatted soybean, concentrated

Reduce soy protein or isolate soy protein, add a certain amount of water and mix with additives

Uniform, forcibly heating, pressurizing and extruding to make the protein molecules neatly arranged,

It produces a tissue structure in the same direction, and at the same time solidifies to form fibrillar protein, and has

It has a chewy feel similar to meat.

Advantages of soybean tissue protein production line

The main body of the soybean tissue protein production line is a twin-screw extruder, with high power and dynamic

The force distribution box system is reliable, with automatic electrification control, with automatic feeding mechanism, and rotary cutting equipment.

The production line has a high degree of automation, easy operation, small footprint and energy saving

Source, less processing loss, and deep processing of soybeans and various grains.

Composition of production line:

Flour Mixer →screw conveyor →Double- screw Extruder →Multi-function Shaper →hoister →Multi-layer Oven → Cooling Belt

END

This production line is developed by our company based on years of experience in extrusion equipment production, combined with advanced equipment at home and abroad. The production line uses defatted soybean meal and peanut shaft as the main raw materials, which are mixed and squeezed and sheared to form a layered fiber structure; its product has a high protein content, has the state and taste of meat, and has the characteristics of oil absorption, water absorption, and taste absorption. Cholesterol and animal fat. Can be widely used in meat products, fast food, quick-frozen food, can also be made into a variety of vegetarian meat snack foods and vegetarian dishes.