The main function of the nutritional powder is to replenish the energy needed by the body. The nutritional powder changes its shape according to the daily food and refines it into powder to suit patients or specific groups of people. For special patients who cannot eat by mouth, nutritional powder can be given through nasogastric tube to ensure the nutrition of the patient. The most commonly used is enteral nutrition powder, which has the advantages of low residue and easy digestion. The nutritional powder for infants and young children is mainly rice noodles, but it cannot replace all the nutrients needed by infants. Choose the corresponding nutritional powder according to different purposes.

Now there are a large number of nutritional meal replacement powders on the market, which mainly use various high-nutrient substances as the main raw materials to produce proteins, oligopeptides, polysaccharides, vitamins, minerals and other nutrients necessary to maintain normal physiological functions of the human body Ingredients and physiologically active ingredients allow the body to receive “direct, high-quality, and continuous” protein supplementation, and the blending of whole grains makes the formula more scientific, reasonable, comprehensive, and nutritional supplementation more balanced, so it can better enhance the body’s immunity and At a healthy level, its products also have the advantages of simple eating method, ready to eat with water, and can be used for soup and porridge. It is the first choice for people with fast-paced healthy eating.

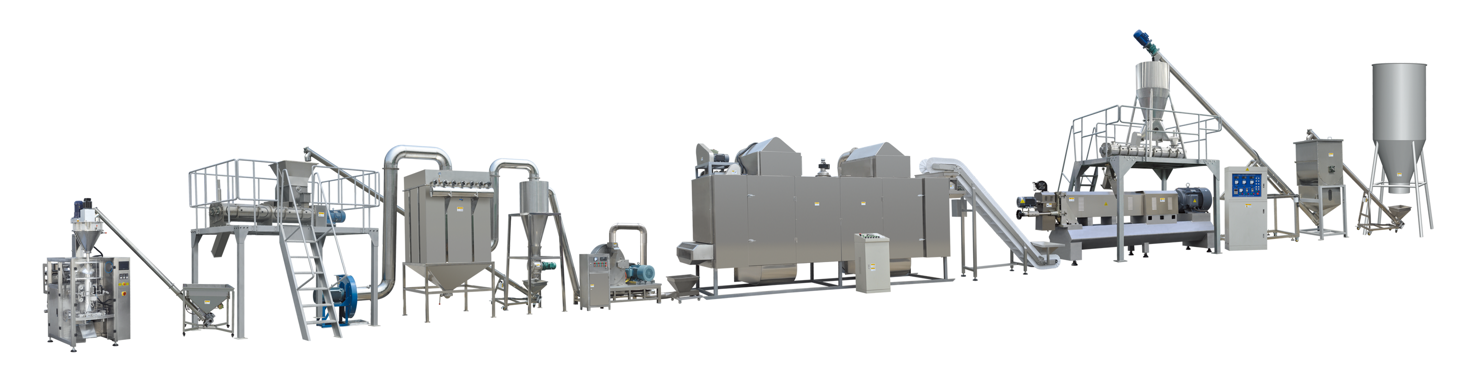

The nutritional powder production line produced by our company uses various grains such as rice, corn and beans as raw materials, and can be extruded, dried, crushed and mixed to produce various nutritional powders, such as baby rice flour, sesame paste and soybean powder. The production line automatically completes the process flow from the start of feeding, with simple operation, no dust leakage, sanitation and energy saving. It can be easily mixed with various raw materials and nutrients.

Configuration introduction:

Bin → screw conveyor → mixer → screw conveyor 2 → twin screw extruder → elevator → oven → automatic pulse crushing unit → double shaft mixing → powder packaging machine

Output: 120~150kg/h, 200~250kg/h, 300~500kg/h, 400~500kg/h, 800~1200kg/h

Sample display

Shandong Arrow Intelligent Equipment Co., Ltd. adheres to the corporate philosophy of “sincere and earnest. Perfect quality, professional and dedicated”, and has a good reputation and reputation in its operations. With the aim of “serving global customers”, we provide all-round consulting and after-sales service in terms of equipment, technology, raw materials, packaging, etc., so as to truly make customers worry-free.