Breakfast is the most important meal of the day, and it should be wholesome and nutritious. Most of us look for instant cereals as we lack time to prepare wholesome meals in the morning. There are better options for breakfast that don’t take much time to prepare.

Corn flakes are made from milled corn, malt flavoring, and sugar. They are fortified with vitamins and minerals. Corn flakes have a crunchy texture, and they soften when soaked in milk. They are one of the most common breakfast cereals in many countries.

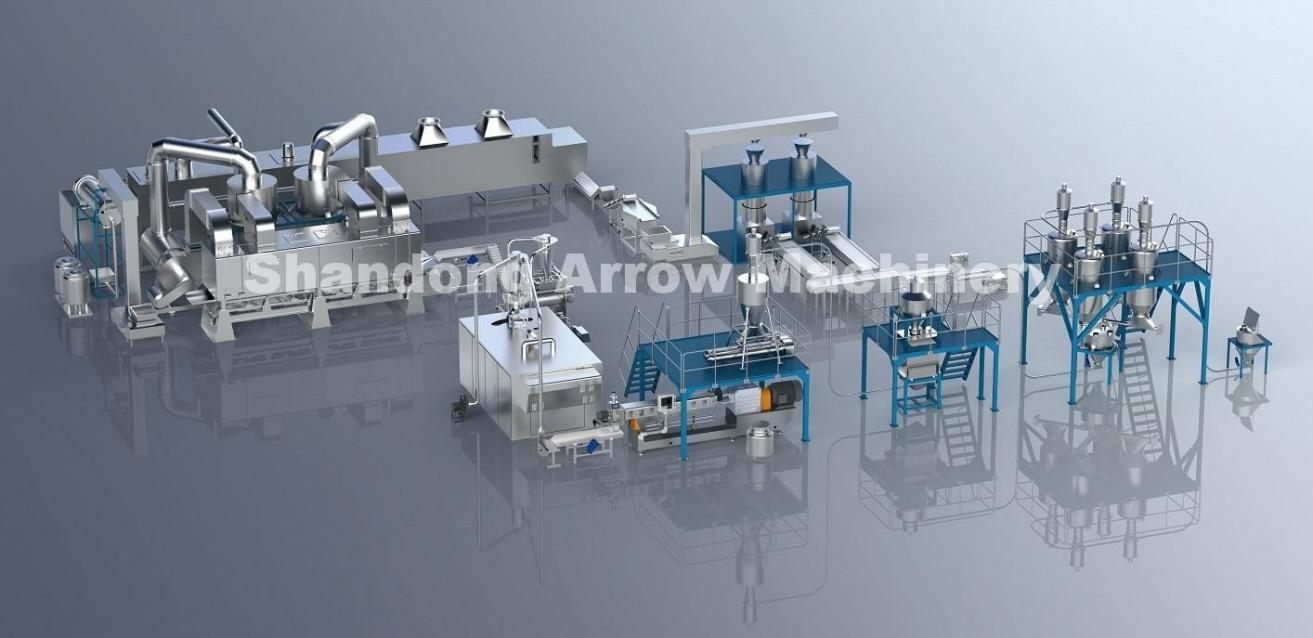

Breakfast cereal corn flakes production procedure

Raw materials: flour of corn, wheat, oat, starch, etc.

A compete production line including raw material preparing system, dosing system, extrusion system, pre-drying system, flaking, high temperature roasting system, coating system, drying system, cooling system and packing system.

Extruder is the core machine, ensure the best extrusion curing effect. Corn flakes made by Shandong Arrow Machinery is kept with the taste and nutrition to the most extend.

The design adopts 3D software 3D design, and coordinate detection are all automatically completed by the computer to ensure the design accuracy requirements.

The extruder is mainly composed of screw extrusion system, transmission system, feeding system, heating system, rotary cutting system and frame. The modular design ensures the convenience and convenience of replacing components, as well as the upgrade ability of subsequent equipment. The equipment selects high-standard food-grade materials to ensure the service life of the extruder and minimize the wear of the screw and cavity. The company has its own extrusion technology engineering laboratory, continuous product research, application development, and can provide strong technical support. We are adhering to the tenet of Arrow: sincerely, make a promise, perfect quality, professional and dedicated standards, provide customers with high-quality services responsibly, help customers solve difficulties encountered in actual production, and continue to create value for customers. Mutual promotion and mutual progress. ARROW and customers learn together, make progress together, and create a better future.

Features:

- The cavity and screw are in combined building block structure, which can adapt to different formulas and raw materials.

- PLC Control system, HMI interface, memory storage function of various parameter settings. Only need to save the craft formulas, it can produce automatically, simple and intelligent. The various parameters of the entire production process are automatically recorded for easy traceability.

- The system has alarm processing function which can better protect equipment and simplify shutdown procedures.

Machine made by Shandong Arrow applies unique design and advance technology to ensure the best performance.

Shandong arrow machinery offer turnkey solutions according to customers’ requirements.