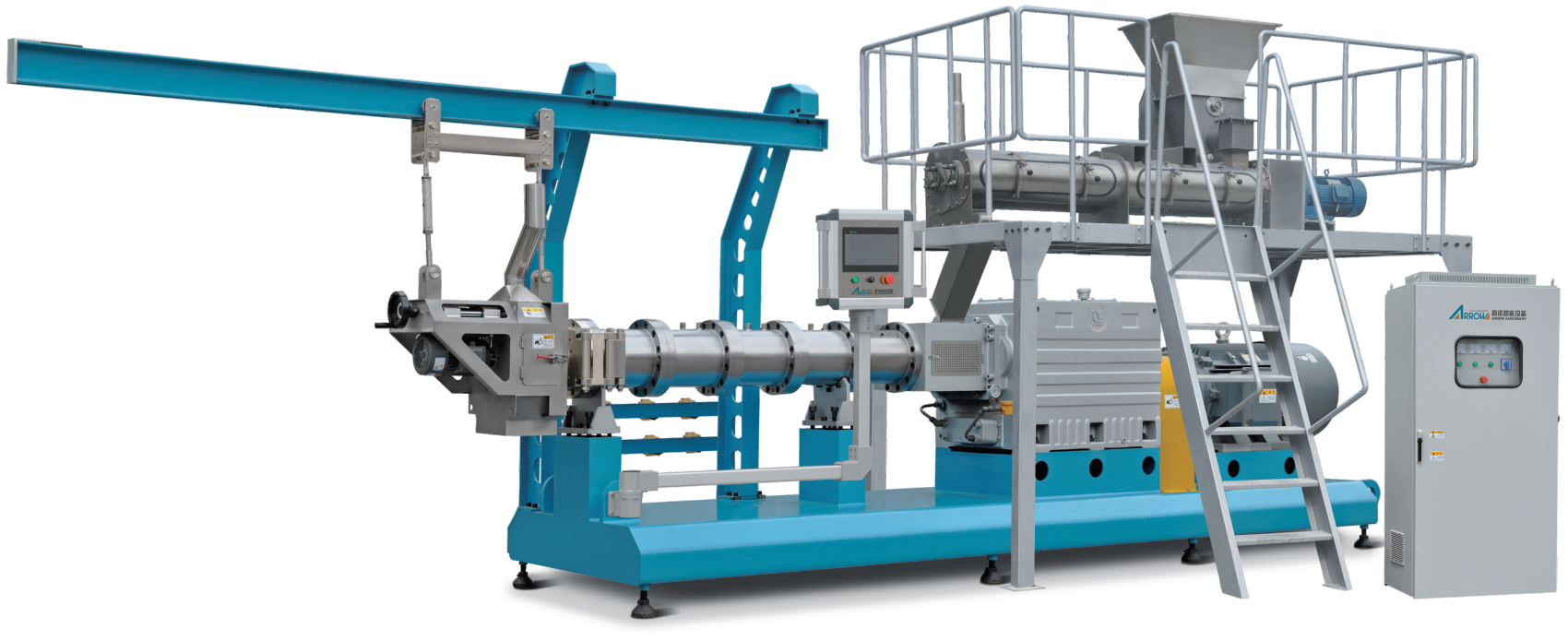

With the development of my country’s aquatic feed industry and the continuous emergence of new processing technologies, it has effectively promoted the improvement of the quality of aquatic feeds. The twin-screw extrusion aquatic feed production line developed by our company learns European technology and adopts a unit screw combined structure. It can realize precise control of production parameters. The aquatic food produced by Arrow smart equipment is high in protein and complete in nutrients. The product can float on the surface or sink into the water. It can be applied to floating and sinking feeds for aquatic products such as fish and shrimps without wasting feed and adding Trace elements can promote the rapid growth of aquatic products.

Aquatic feed is a bait specially provided for aquatic animal breeding. According to the feeding species, aquatic feed can be divided into fish feed, shrimp feed and crab feed; according to the characteristics of feed, it can be divided into compound feed, concentrated feed and pre-mixed feed. The raw materials for aquatic feed production are mainly composed of fish meal, grain raw materials and fats. Fish meal and grain raw materials often account for more than 50% of the feed cost.

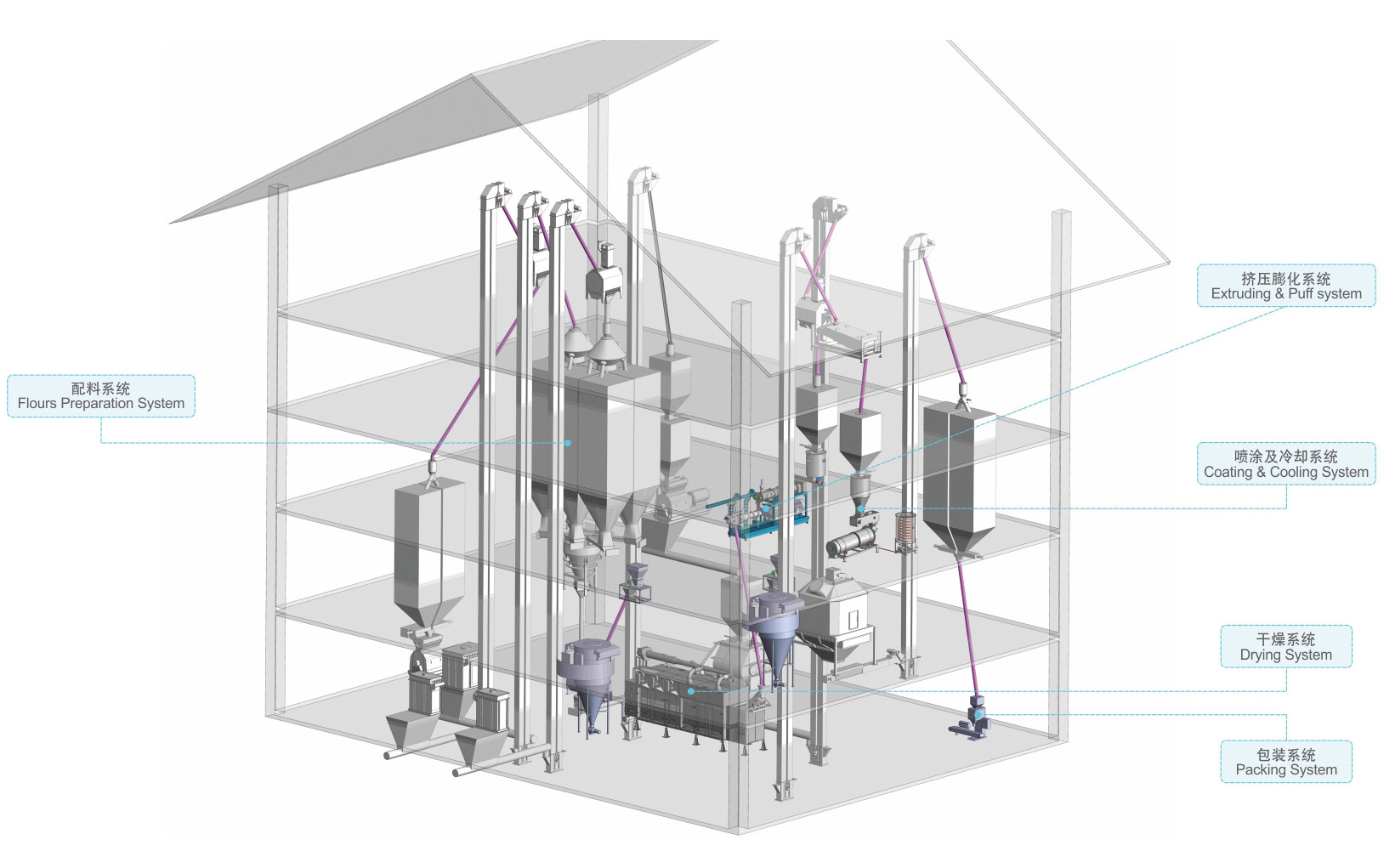

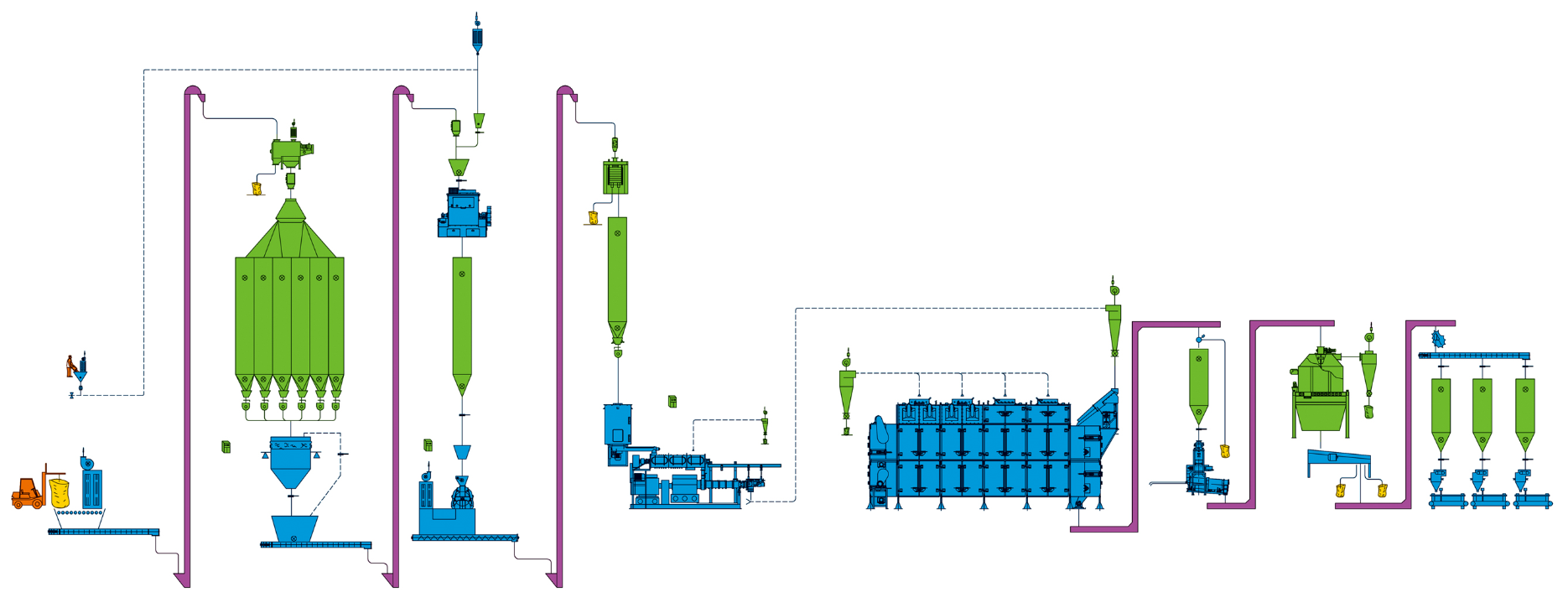

1.Process flow

①Batching②Grinding③Mixing④Tempering⑤Extruding⑥Drying⑦Coating⑧Cooling⑨Packaging

2.Prodcution Case

3.Product Category

Aquatic feed such as floating/sinking fish and shrimp feed.

4.Capacity

500kg/h,800-1000kg/h,1000-1500kg/h,1500-2500kg/h,3000kg/h,5000kg/h。

5.Product Description

The aquatic product produced by the twin-screw extruder of our company has high protein and complete nutrients. It can be applied to various fish and shrimp aquatic products. The addition of trace elements can promote the growth of aquatic products and pets. It is ideal for different manufacturers in principle.

6.Sample Display

Shandong Aroow Machinery Co., Ltd. is one of China’s relatively large-scale puffed food machinery processing equipment and whole plant engineering comprehensive problem solver with extruder as the main body. The aquatic product produced by the company’s twin-screw extruder has high protein, complete nutrients and water absorption. It is fast, softens in time, has less dissolution loss, and does not collapse. Tempering and gelatinization is good for absorption, improving feed utilization rate and saving materials. Good absorption also reduces the nutrition of water and is more conducive to aquatic health. It can be applied to various fish and shrimp aquatic products, and it is the best choice for aquatic feed manufacturers.