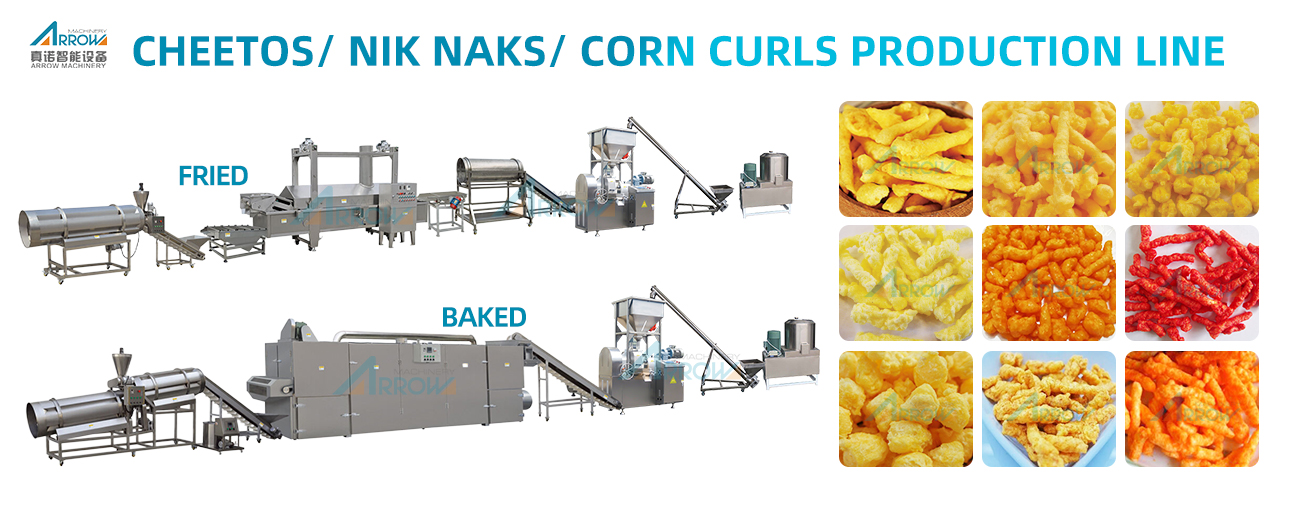

Kurkure/ Cheetos are kind of special extruded snacks, very crunchy and delicious in taste. They are made by a special extrusion process. The corn grits are moisturized by water in the flour mixer and fed to the Rotary Head Extruder. In the extruder, due to the rubbing of two rotary plates, the corn grits are squeezed and twisted to curls shapes. The cutting knives can cut them into required length.

The Kurkure/ Cheetos can be fried in fryer or toasted in oven and then cooled before flavoring.

Seasoning is sprayed onto their surface to get different delicious tastes. Due to their delicious tastes and nutrition, they are quite popular with consumers.

Shandong Arrow Cheetos/ Nik naks/ corn curls production line with “Low cost, high profits”

The Kurkure/ Cheetos can be fried in fryer or toasted in oven and then cooled before flavoring.

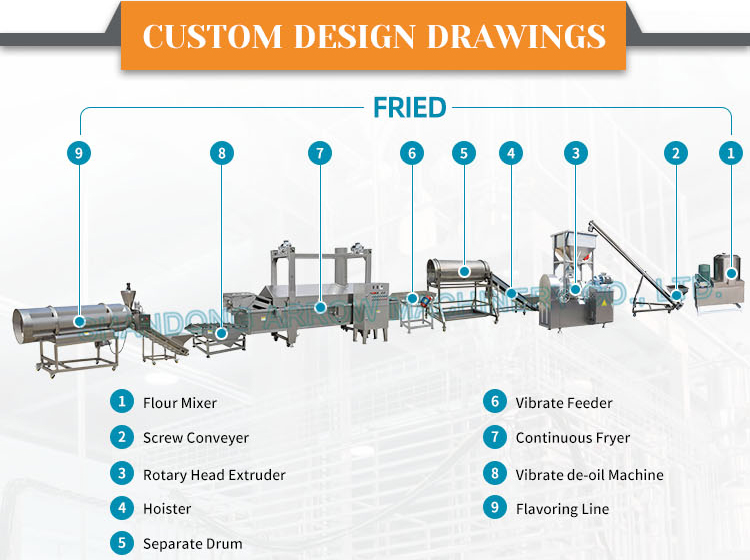

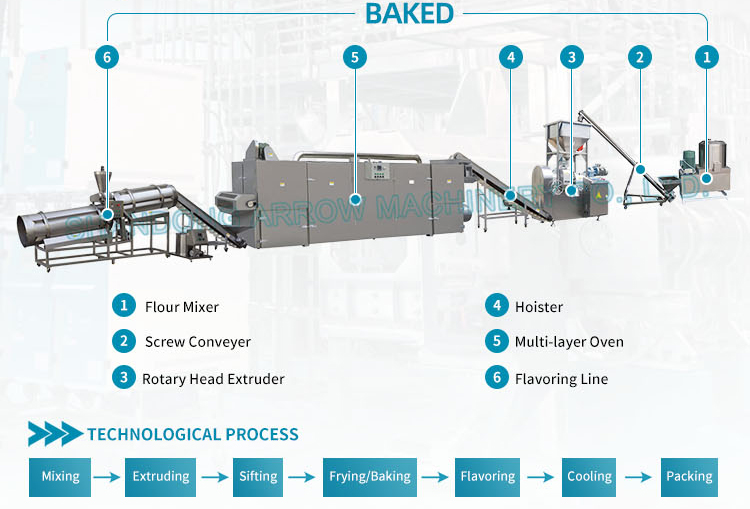

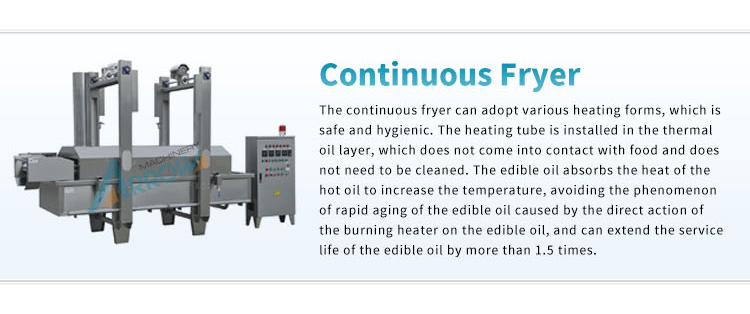

Flour Mixer→Screw Conveyer→Rotary Head Extruder →Hoister→Separate Drum→Vibrate Feeder→Continuous Fryer→Vibrate de-oil Machine→Flavoring Line Arrow Cheetos/ Nik naks/ corn curls production line is highly automatic and high efficiency. This Cheetos/ Nik naks/ corn curls production line adopt twin-screw extrusion technology and are highly flexible. Corn curls making machine can produce various uncoated, coated or filled cereal based snacks with a wide variety of recipes and shapes.

Flour Mixer→Screw Conveyer→Rotary Head Extruder →Hoister→Separate Drum→Vibrate Feeder→Continuous Fryer→Vibrate de-oil Machine→Flavoring Line Arrow Cheetos/ Nik naks/ corn curls production line is highly automatic and high efficiency. This Cheetos/ Nik naks/ corn curls production line adopt twin-screw extrusion technology and are highly flexible. Corn curls making machine can produce various uncoated, coated or filled cereal based snacks with a wide variety of recipes and shapes.

Kurkure, Cheetos, Nik naks, Extruded Snack Sticks, and Other Puffed Shapes, we want to make your next big idea a reality.

Features Of Corn Puff Snack Food Production Line

1. Easy to control by automatic production line.

2. Optional fillings for cooking makes it easy to prepare all of the raw materials.

3. Using the corn as the raw material, having the benefit of easy to getting and low budget.

4. No wasting from being fully utilized of the raw materials.

5. Adjustable feeding speed according to the production requirements.

6. Variety of different shape product by replacing mold easily.

7. The cutting device of the extruder has a cover to ensure safe operation.

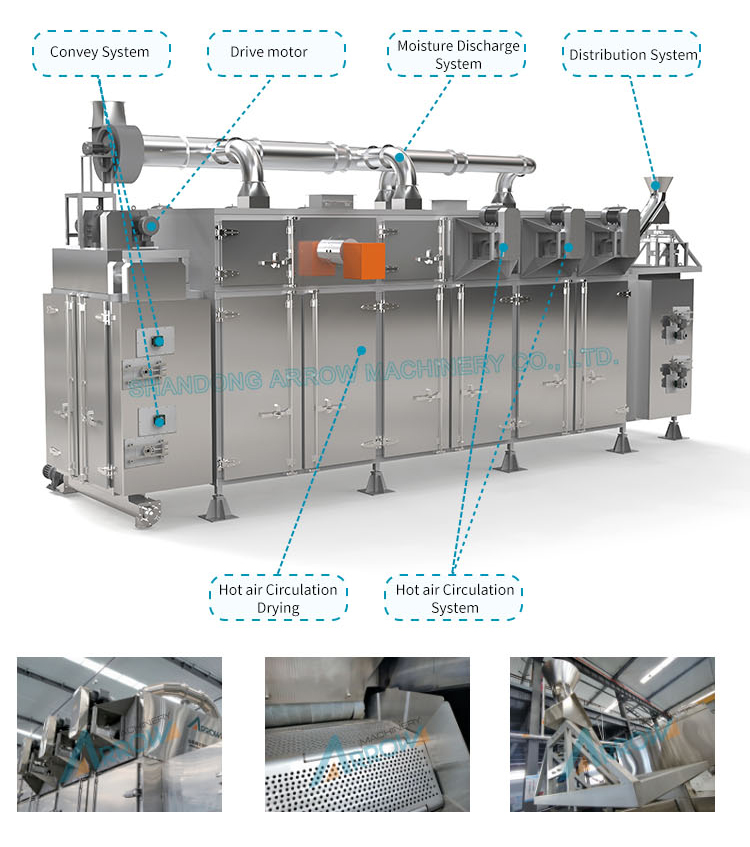

8. Adjustable baking or drying temperature and time.

9. Equipped with the temperature display and control device.

10. Insulation device to improve thermal efficiency.

11. Optional round and rectangular product cutting machine according to the requirements.

12. The powder sprinkler feeds the seasonings with a screw, and the amount of powder can be adjusted according to the requirements.

13. Integrated, safe and hygienic seasoning drum.

14. The equipment of the whole production cycle is made of stainless steel which is hygiene and easy to clean.