| model | installed power | output |

| AHT 62 | 75 KW | 100-350 KG/H |

| AHT 72 | 110 KW | 200-700 KG/H |

| AHT 95 | 200 KW | 800-1200 KG/H |

| AHT 120 | 280KW | 2000-3000KG/H |

1.Description

Extruder consist of Heating,Feeding,Cooling,Controlling,Driving system.

2.Introduction

(1).Heating: Accurate ,individual heating for different zones, ±1 degree controlling,

(2). Feeding: Accurate weigh or forced powder feeding, or Pressure liquid metering feeding operation for high-end production processing.

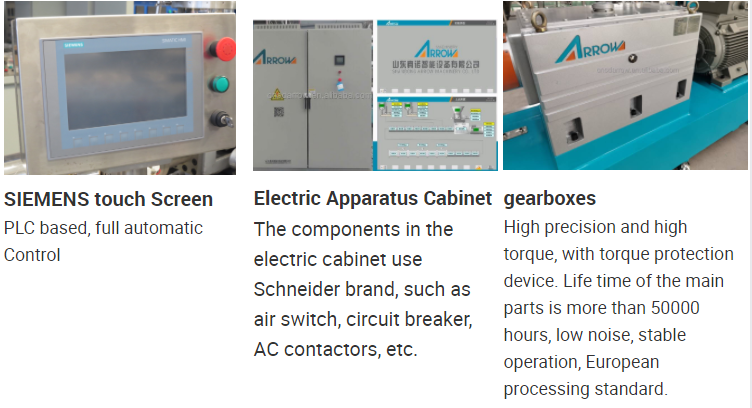

(3).Controlling: Adopt Euro,US,Japan brand top brand PLC (Siemens,Delta )controlling, electrical

(4).Driving: Well-known famous Siemens ABB motor provide strong,powerful output , energy transferred by high-end gear box, guarantee stable performance. With safety heavy loading, and torque protection. Professional manufacturing and processing. This will ensure the accuracy and coordination among each component of the Extruder. Stable processing and low noise is the best proof.

3.Key components

(1). Barrel

1). Modular design, multi like 3/5/8 segments for different production, easy change,replace,cost-saved

2). High strength carbide steel

3). Square/Round design, High resistance

4). Each zone with its own water cooling design

5).Heating and cooling medium of each barrel can be operated independently, as well, the temperature can be controlled independently

(2). Screw

1). Modular design,easy change,replace,cost-saved

2). High strength carbide steel,high resistance

3). 3D design,CNC cutting, surfce smooth, high conjunction accuracy.

4). Different combination of convey,kneading,mixing,puffing segments meet different demand of various application

5).Precise food technology and material selection, which assure the using life of the extruder, minimizing the wear

and tear of the screw and barrel.

(3). Gear Box

1). High Torque design,heavy loading

2). Safety protection, with automatic lubrication

3). High-end gears bearing fabricated, assembled